CE Mark & Specifications

For information about the batteries identified with the CE mark, review the PDF below.

Product Design

First Battery’s technical department is made up of qualified and experienced staff with an in-depth knowledge of lead-acid battery systems. All products are designed on Catia V5 systems making use of simulation software for checking battery design, performance capability, product capacity and manufacturing capability. Rapid prototyping also keeps us at the forefront of innovation.

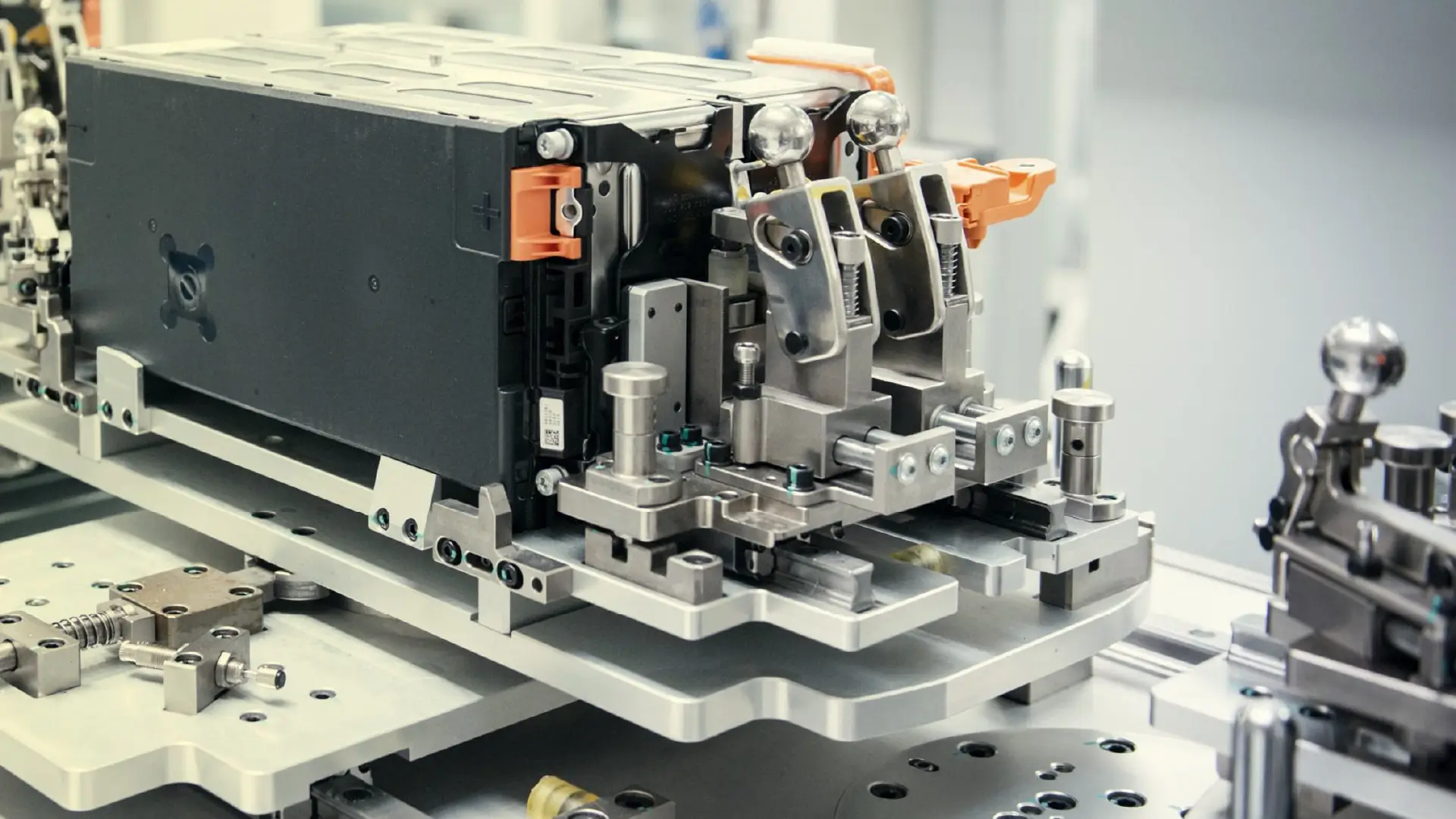

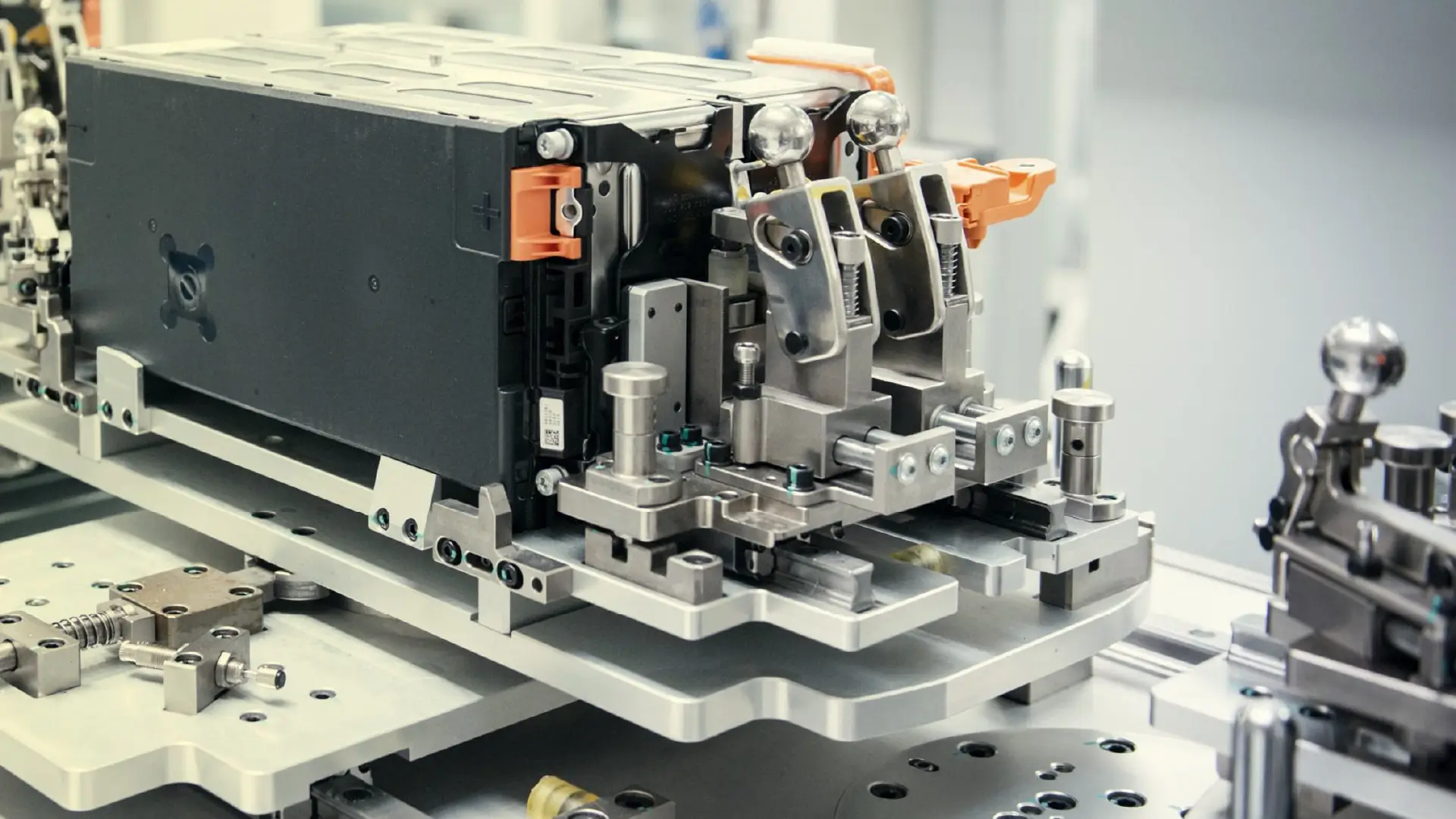

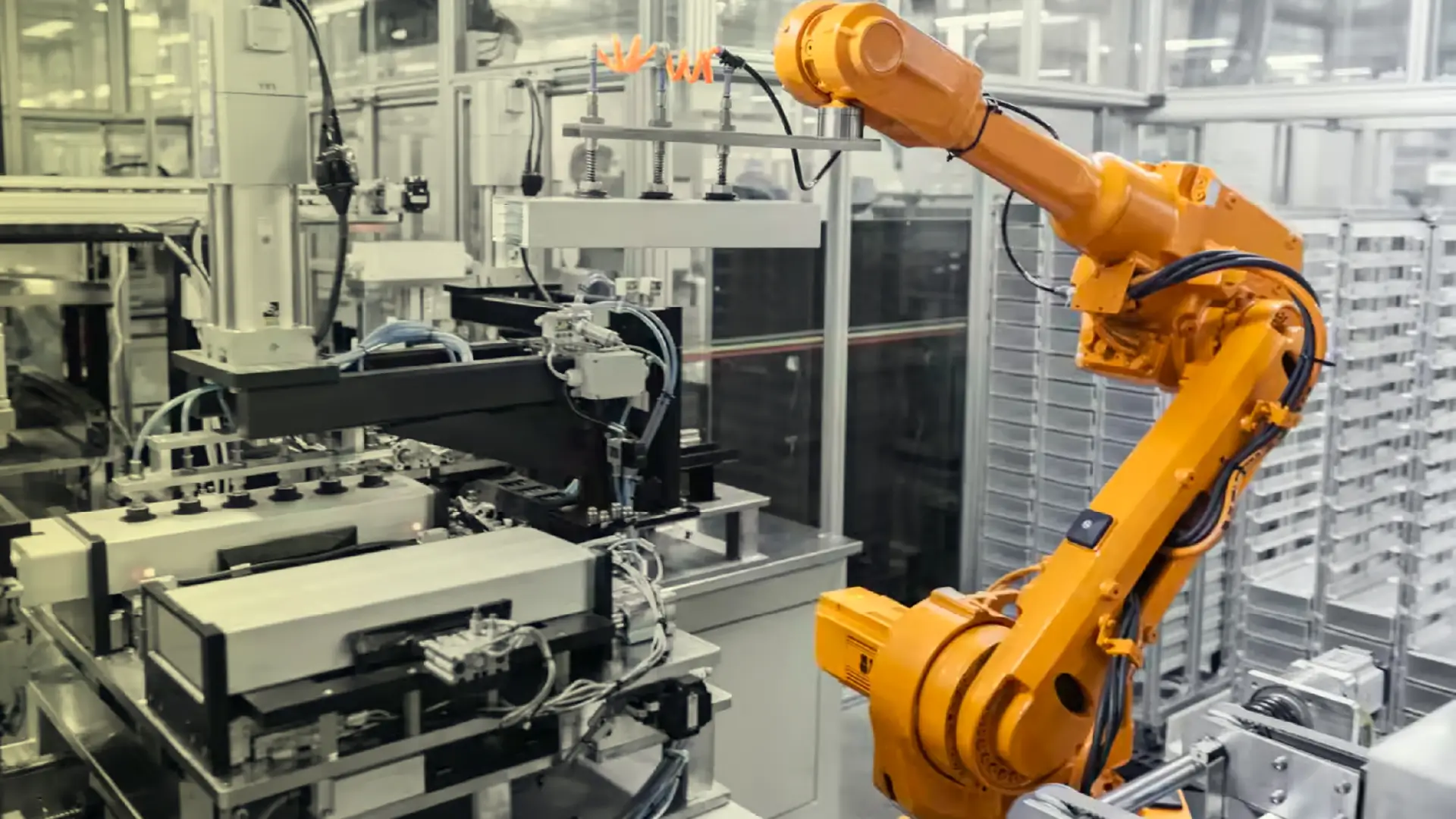

Production & Manufacturing

The modern design processes used by First Battery result in all of our products and their components being fully recyclable. Our in-house tooling capability enables us to produce highly complex moulds for plastic component production. When it comes to manufacturing, we use only the best equipment at our four dedicated, vertically integrated manufacturing plants.

Advanced Product Testing

The team of experts at First Battery has the expertise and state-of-the-art facilities to conduct chemical analysis, metallurgical evaluation and performance tests. More advanced testing is conducted in collaboration with CSIR and selected universities. Sophisticated software utilised by our skilled and qualified personnel enables us to fast track innovation and remain at the forefront of new capabilities and technological advances.

Project Management

All in-house projects are expertly managed from conceptualisation all the way through to implementation. Our team ensures every detail is attended to and uses the most sophisticated software including CAD, Wonderware and MS Project.

CE Mark & Specification

For information about the batteries identified with the CE mark, review the PDF below.

Product Design

First Battery’s technical department is made up of qualified and experienced staff with an in-depth knowledge of lead-acid battery systems. All products are designed on Catia V5 systems making use of simulation software for checking battery design, performance capability, product capacity and manufacturing capability. Rapid prototyping also keeps us at the forefront of innovation.

Production & Manufacturing

The modern design processes used by First Battery result in all of our products and their components being fully recyclable. Our in-house tooling capability enables us to produce highly complex moulds for plastic component production. When it comes to manufacturing, we use only the best equipment at our four dedicated, vertically integrated manufacturing plants.

Advanced Product Testing

The team of experts at First Battery has the expertise and state-of-the-art facilities to conduct chemical analysis, metallurgical evaluation and performance tests. More advanced testing is conducted in collaboration with CSIR and selected universities. Sophisticated software utilised by our skilled and qualified personnel enables us to fast track innovation and remain at the forefront of new capabilities and technological advances.

Project Management

All in-house projects are expertly managed from conceptualisation all the way through to implementation. Our team ensures every detail is attended to and uses the most sophisticated software including CAD, Wonderware and MS Project.